Modern Manufacturing Powered by Material Innovation

Introduction

In the past century, the global manufacturing sector has undergone a remarkable transformation, driven by rapid advancements in engineering, chemistry, and material science. Industries today operate within a far more complex, interconnected, and technology-enabled environment than ever before. The performance standards expected of materials have risen dramatically, and the demand for reliability, efficiency, and sustainability has propelled continuous research and innovation. While manufacturing once relied heavily on a limited set of raw materials, the present landscape incorporates an expansive range of engineered compounds, specialty polymers, functional coatings, composites, and scientific formulations.

In contemporary industrial discussions, various specialized materials surface as part of broader analyses on performance and processing—sometimes including formulations referenced in technical literature such as PVA—yet the purpose of this article is not to highlight individual materials, but to explore the comprehensive evolution of the entire material ecosystem that enables the industrial world to function with increasing precision and sustainability.

This long-form analysis examines the evolution, applications, economic implications, and future potential of modern materials that support manufacturing on a global scale.

1. Evolution of Material Expectations in Industry

1.1 From Basic Necessities to Engineered Solutions

During the early phases of industrialization, material selection was largely based on availability rather than strategic engineering. Wood, iron, and natural fibers dominated production systems. As production scaled, industries began seeking materials that delivered more consistent performance and predictable behavior.

1.2 Rise of Synthetic and Semi-Synthetic Materials

The introduction of polymers, resins, emulsions, and synthetic fibers revolutionized production capabilities. These engineered solutions provided manufacturers with the ability to fine-tune mechanical properties such as flexibility, tensile strength, and resistance to moisture or heat.

1.3 Integration of Material Science as a Core Discipline

By the mid-20th century, material science matured into a formal academic and industrial field. Researchers studied materials at molecular and structural levels, paving the way for specialized materials tailored for unique operational requirements.

1.4 Shift Toward Interdisciplinary Innovation

Today’s materials result from collaborations across chemistry, engineering, data science, nanotechnology, and environmental science. This interdisciplinary approach has led to the development of high-performance coatings, nano-enhanced composites, and energy-efficient functional materials that support advanced industrial applications.

2. Key Properties Desired in Contemporary Industrial Materials

2.1 Structural Reliability

Industrial processes demand materials capable of withstanding repeated mechanical, thermal, and chemical stress. This reliability ensures consistent production output and long-term product durability.

2.2 Processing Flexibility

The adaptability of materials—whether to form films, coat surfaces, bind substrates, or support fabrication—determines their usefulness across multiple industries. Processing flexibility reduces cost and enables greater innovation.

2.3 Compatibility With Other Compounds

Many industrial systems rely on multi-material formulations. Compatibility in emulsions, adhesives, coatings, and composite structures is essential for maintaining uniform performance.

2.4 Controlled Reactivity and Stability

Materials must demonstrate predictable behavior under conditions such as heat curing, cooling, drying, or exposure to humidity. Controlled reactivity ensures safe and efficient manufacturing.

2.5 Environmental Safety

With sustainability now central to industrial strategy, materials must meet environmental guidelines that regulate toxicity, biodegradability, emissions, and waste impact.

3. Application Across Key Manufacturing Sectors

3.1 Packaging and Protective Films

High-performance films and protective layers rely on engineered materials capable of delivering clarity, strength, moisture control, and barrier properties. These films are widely used in consumer packaging, medical applications, and specialized industrial environments.

3.2 Textiles and Fabrication

Textile manufacturing utilizes a diverse set of materials that impact fiber performance, dye uptake, abrasion resistance, and tensile strength. The integration of scientific formulations during spinning and weaving supports smoother operations and higher-quality fabric finishes.

3.3 Adhesives, Binders, and Coatings

Bonding agents, surface coatings, primers, and industrial adhesives depend on materials that provide uniform application, stable adhesion, and protective sealing. Engineering refinements in this sector have improved product longevity and reduced material waste.

3.4 Construction and Infrastructure

Specialized materials contribute to the strength, durability, and functionality of modern construction. Additives, reinforcement fibers, waterproofing layers, and surface protectants each play crucial roles in shaping the structural integrity of buildings and infrastructure projects.

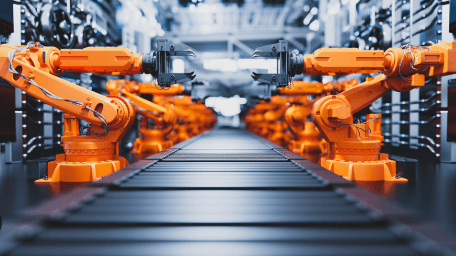

3.5 Automotive and Industrial Machinery

Automotive innovation increasingly relies on lightweight materials, temperature-resistant coatings, shock-absorbing composites, and high-precision components. Material evolution supports fuel efficiency, safety, and the integration of advanced electronics.

3.6 Electronics and High-Tech Manufacturing

Electronics manufacturing depends on materials with controlled conductivity, insulation properties, thermal stability, and precision processing capabilities. Modern devices require micro-scale components that demand exact material behavior.

4. Technological Advancements Driving Material Innovation

4.1 Automation and Digital Material Engineering

Digital modeling, AI-enhanced simulations, and automated manufacturing have enabled unprecedented precision in material design. Manufacturers can now predict how materials will behave under specific conditions before producing physical prototypes.

4.2 Additive Manufacturing

Additive manufacturing (3D printing) expands the possibilities of material usage, allowing for intricate geometries and reduced waste. New printing-compatible materials support the production of complex structures that traditional manufacturing cannot achieve.

4.3 Nanotechnology and Molecular Engineering

Nanomaterials and molecular modifications enable enhanced surface properties, improved conductivity, and customized reactivity. These technologies continue to revolutionize coatings, electronics, medical devices, and energy solutions.

4.4 Smart Materials and Responsive Systems

Engineered materials that respond to stimuli—such as temperature, pressure, or light—are increasingly important in robotics, aerospace, biomedical engineering, and next-generation electronics.

5. Sustainability at the Center of Material Progress

5.1 Regulatory Influence

Global regulations concerning environmental performance shape material selection across industries. Compliance requires reduced emissions, safer formulations, and waste-conscious production practices.

5.2 Rise of Green Chemistry

Green chemistry innovations focus on minimizing hazardous substances, reducing waste, and designing materials with improved biodegradability or recyclability.

5.3 Energy Efficiency and Reduced Resource Consumption

Advanced materials contribute to more energy-efficient processes by improving insulation, reducing production temperatures, and enabling lighter-weight components.

5.4 Recycling and Circular Economy Models

Material engineering now includes designing for recyclability from the outset. Industries increasingly prioritize materials that can re-enter manufacturing cycles without degradation.

5.5 Bio-Based Alternatives

The search for plant-derived polymers, biodegradable plastics, and renewable composite materials reflects industry movement toward a more sustainable future.

6. Economic and Operational Factors Affecting Material Usage

6.1 Market Volatility

Global supply chains, geopolitical factors, and resource availability directly influence material pricing and access. Manufacturers must adapt to fluctuating conditions through strategic sourcing and risk management.

6.2 Procurement and Vendor Evaluation

Selecting reliable material suppliers is a strategic process that involves analyzing consistency, technical support, product documentation, and long-term availability.

6.3 Cost vs. Performance Optimization

Modern operations require a balance between cost control and achieving high-performance standards. Material engineers evaluate mechanical, chemical, and environmental properties against budget targets.

6.4 Inventory and Logistics Management

Efficient supply chains reduce downtime and ensure steady production flow. Material reliability is critical for avoiding disruptions that can impact output quality and delivery schedules.

7. Future Trends in Material Research and Industrial Development

7.1 High-Strength Composites

Innovations in composite materials will enhance strength-to-weight ratios, opening possibilities in aerospace, automotive, and construction applications.

7.2 Precision-Engineered Polymers

Advanced polymer engineering will allow materials to be designed with specific molecular structures tailored to unique industrial requirements.

7.3 Smart Manufacturing Integration

As Industry 4.0 evolves into Industry 5.0, human-machine collaboration will rely on materials that support automation and adaptive processing.

7.4 Renewable Energy Integration

Materials will play an increasingly critical role in the development of solar panels, energy storage systems, and sustainable infrastructure.

7.5 Advanced Surface Science

Future coatings and surface treatments will provide improved resistance, self-healing properties, energy efficiency, and intelligent functionality.

Conclusion

The world of industrial materials is undergoing continuous reinvention. What began as a dependency on basic natural resources has evolved into a sophisticated ecosystem of engineered formulas, advanced polymers, functional coatings, and cutting-edge composites. Manufacturers across the globe rely on these innovations to achieve greater precision, reliability, sustainability, and cost efficiency.

Material science remains at the forefront of industrial progress, supported by technological advancement, environmental responsibility, global collaboration, and the ongoing pursuit of quality. As industries adapt to new challenges and embrace modern methodologies, materials will continue to define the possibilities of the next generation of manufacturing.